Gulf Coast Oil Spill Response Program

Materials Provided

- Bulk and intermediate sized containers (275 gal.) of CytoSol™ BioSolvent are staged at key service ports for response personnel.

- 5,000 gallons of CytoSol™ are currently available in 275-gallon totes in New Orleans, Louisiana.

- 150,000 gallons of additional CytoSol™ product is available in the Louisiana region within 24 hr.

- Larger volumes can be mobilized as required to respond to shoreline cleaning and de-con activities from Texas through the Florida coasts.

Equipment Required

Product can be sprayed from response vessels on to slick or mats of stranded oil.

- Low pressure hand powered sprayers and/or 12 volt low pressure sprayers with dispenser wands.

- Shallow draft marine vessels and skiffs.

- Skimmers and oil recovery booms to collect bulk crude oil released by CytoSol™ process.

- Oil recovery secondary containment

- Oil absorbent boom and pads for collection of residual hydrocarbons.

- Recovered oil tanks and containers to transport the collected oil-CytoSol™ mixture back to ports or barges for recycling.

Expertise Required/Offered

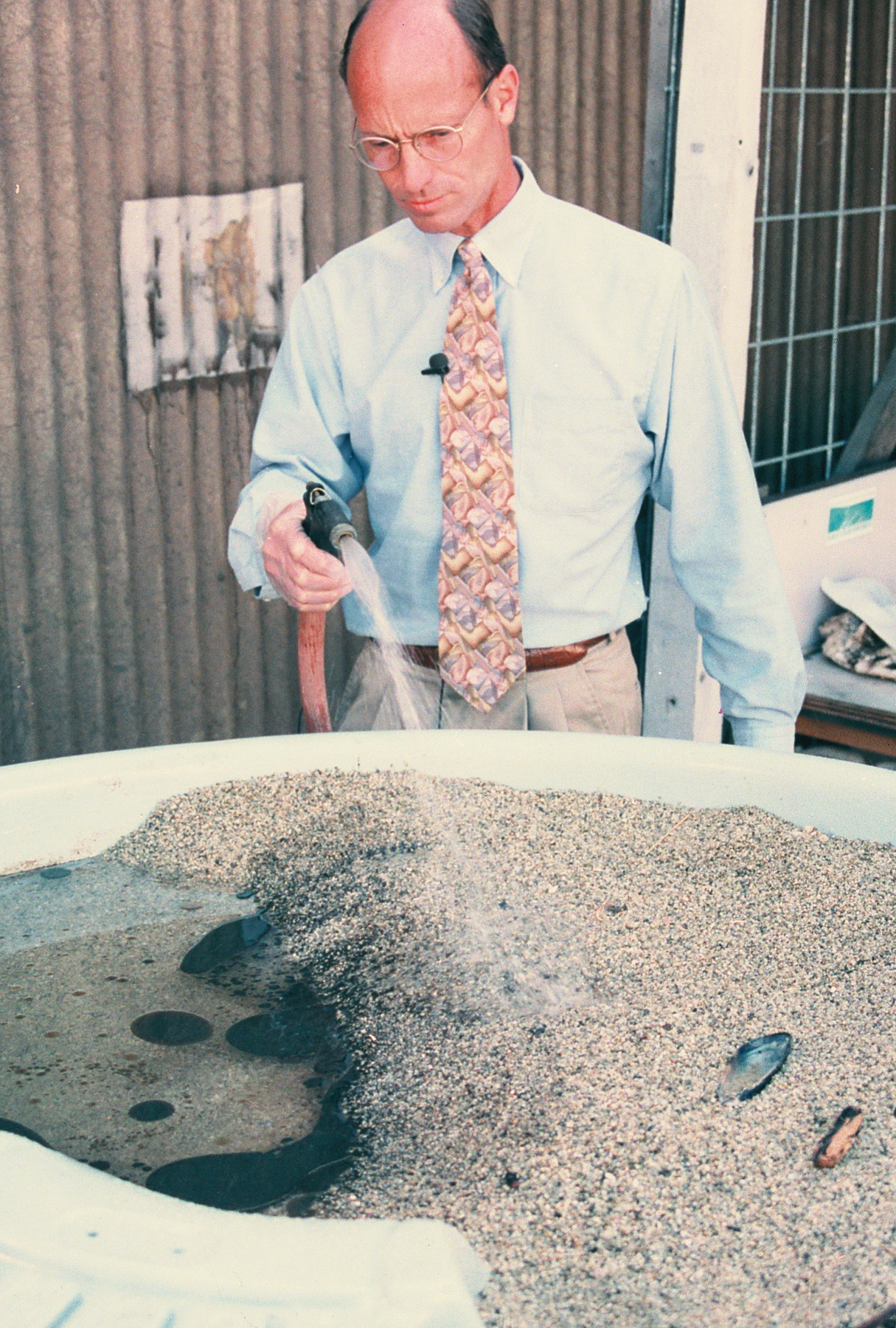

- Shoreline cleaning personnel trained to apply CytoSol™ BioSolvent and to recover released oil using a gentle water deluge.

- Product handling and application training will be provided by CytoCulture’s team headquartered at our Response Center with Rapid Energy Services in Lafayette.

- CytoSol was deployed by the O’Brien Group during the 2007 San Francisco Bay spill for the de-con of oiled response vessels in the water as well as cleaning up oiled boom, pumps, and equipment.

- Marine toxicity studies and case history field trials involving the cleaning of crude oil from oiled mussel beds, oiled marsh plants, oiled creek beds and oiled shorelines along the San Francisco Bay.

CytoCulture operates a microbiology laboratory to monitor bacteria populations in shoreline sediments as well as monitoring degradation of petroleum oil in sediments and the water column over time. In order to advance residual removal, the CytoSol™ Process can be used in conjunction with the Proteus 168 Surface Washing Product (listed on EPA's NCP list as HE1000). The Proteus 168 is intended as a water soluble follow up to the CytoSol™ application to accelerate the biodegradation of residual contaminants in sediments after the bulk of the oil has been recovered.

Shoreline Cleaner using CytoSol™ BioSolvent made from Vegetable Oil

The three most important things to keep in mind:

- The CytoSol™ Process was developed under USDA grants to facilitate the recovery of spilled heavy petroleum from oiled shorelines in ecologically sensitive marine and aquatic habitats.

- The process uses a 'Biosolvent' formulated with methyl esters of vegetable oils and animal fats along with oleophilic nutrients to enhance the biodegradation of residual hydrocarbons. The methyl esters have a strong solvent activity capable of dissolving weathered crude oil from shoreline habitats including marshes.

- The CytoSol may also facilitate the recovery of oil mats threatening shorelines inside small bays and estuaries.